11-Feb-2026

In today’s

fast-paced construction and infrastructure industry, speed, accuracy,

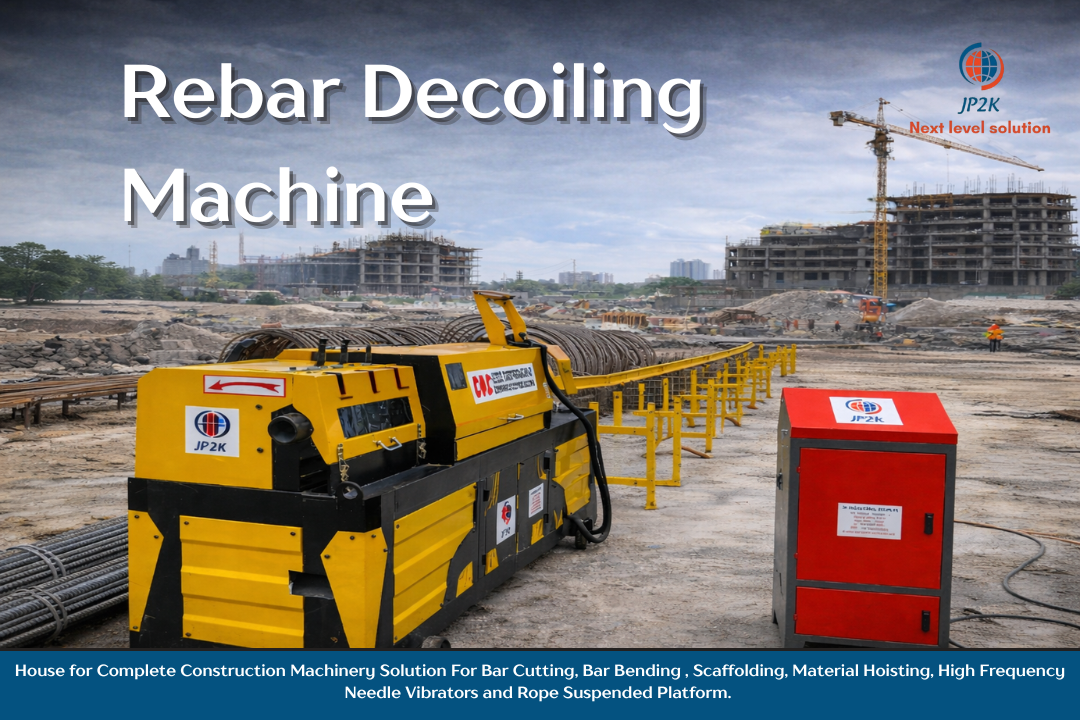

and efficiency in steel processing are critical. A Rebar Decoiling Machine

plays a vital role in modern rebar fabrication by converting coiled steel bars

into straight, usable rebars for cutting, bending, and stirrup production.

From residential

construction to large-scale commercial and industrial projects,

rebar decoiling and straightening machines have become an essential part of rebar

processing equipment.

A rebar

decoiling machine is designed to uncoil, straighten, and feed steel

rebars (TMT, cold-rolled, or reinforcement bars) from coils. These machines

are commonly integrated with:

Bar

bending machines, CNC stirrup bending machines, Automatic rebar straightening

and cutting machines, CNC rebar production lines

They significantly reduce manual labour, improve safety, and increase productivity on construction sites.

1.

Automatic Rebar Decoiling Machine

An automatic

rebar decoiler ensures continuous, smooth feeding of steel bars with

minimal operator intervention. Ideal for high-volume rebar fabrication

plants.

2.

Rebar Straightening and Cutting Machine

This

machine combines decoiling, straightening, and cutting in a single line,

widely used by construction contractors and prefab rebar units.

3.

Hydraulic Rebar Decoiling Machine

Designed

for heavy-duty applications, hydraulic decoilers are suitable for large-diameter

TMT bars and infrastructure projects.

4.

Portable Rebar Decoiler for Construction Sites

Compact

and easy to transport, these machines are perfect for on-site rebar

processing, especially for local construction companies and small

contractors.

5. CNC

Rebar Decoiling & Production Line

Integrated

with CNC stirrup bending machines and cutting systems, these are used in industrial

rebar processing plants and commercial construction companies.

Rebar

decoiling machines are widely used in:

Residential

building construction, Commercial building contractors, Industrial construction

projects, Infrastructure projects (bridges, highways, metros), Pre-fabricated

rebar machinery units, Modular construction & modular office buildings, Home

construction companies, Civil construction and engineering projects

High

production speed, Uniform

straightening accuracy, Reduced steel wastage, Improved site

safety, Lower labor dependency, Seamless integration with bar

bending & cutting machines, Consistent quality for stirrups and

reinforcement bars

A rebar

decoiler for bar bending machines ensures uninterrupted steel feeding,

making it ideal for:

CNC

stirrup bending machine decoilers, Rebar coil straightening machines for

stirrups, Reinforcement bar decoiler-straightener systems

This setup

is widely used by general contractors, construction management firms,

and design-build contractors.

The rebar

decoiling machine price in India depends on:

Bar

diameter capacity, Speed and automation level, Hydraulic or mechanical system, Integration

with straightening & cutting line, Custom steel bar processing requirements

Prices

typically vary for:

Automatic

rebar straightening and cutting machine price, High-speed steel bar decoiling

machine, Heavy-duty industrial rebar processing machine

India has

a growing demand for rebar processing machinery due to rapid

urbanization and infrastructure development. Reliable manufacturers supply

machines across:

Hyderabad,

Delhi, Ahmedabad, Pan-India construction hubs

When

choosing the best rebar decoiler supplier, look for:

Strong

after-sales service, Availability of spare parts, Custom machine options, Local

service support

Ideal for:

Construction

companies, Commercial general contractors, Rebar fabrication units, Home

builders and remodeling companies, Civil & structural engineering firms, Infrastructure

project contractors

Whether

you are searching for “rebar decoiling machine near me” or planning to buy

rebar decoiling machine for large-scale projects, investing in the right

equipment ensures long-term cost savings.

With

increasing demand for faster project completion, higher structural

quality, and lower labor dependency, rebar decoiling machines have

become indispensable in:

Construction

project management, Building design and construction, Industrial and commercial

construction services

They

support automation, precision, and scalability in rebar preparation and

fabrication.

A Rebar

Decoiling Machine is no longer optional—it is a necessity for efficient,

safe, and high-quality construction. Whether used as a standalone decoiler

or part of a CNC rebar processing line, it significantly enhances

productivity and consistency.

If you are involved in residential, commercial, or industrial construction, choosing the right rebar decoiling and straightening machine can transform your steel processing operations.